Giải pháp toàn diện cho mọi nhu cầu sản xuất của doanh nghiệp

Các dịch vụ sản xuất trực tiếp tại nhà máy, được thiết kế dành riêng cho khách hàng B2B đang tìm kiếm giải pháp sản xuất ổn định, chất lượng cao và lâu dài.

Chúng tôi chuyên cung cấp dịch vụ OEM (Original Equipment Manufacturing) và sản xuất theo dự án tùy chỉnh. Năng lực sản xuất linh hoạt cho phép chúng tôi đáp ứng chính xác yêu cầu của bạn — từ các sản phẩm tiêu chuẩn được tùy chỉnh thông số cho đến những thiết kế hoàn toàn mới.

Gia công sản phẩm đúng theo bản vẽ, thông số kỹ thuật và tiêu chuẩn riêng của khách hàng

Đáp ứng từ giai đoạn mẫu thử cho đến sản xuất hàng loạt quy mô lớn

Sản phẩm được đóng gói và gắn thương hiệu theo yêu cầu của doanh nghiệp bạn

Mỗi dự án có quản lý riêng để điều phối tiến độ, chất lượng và giao hàng

Đội ngũ kỹ sư giàu kinh nghiệm của chúng tôi cung cấp hỗ trợ kỹ thuật toàn diện trong suốt quá trình phát triển sản phẩm và sản xuất. Chúng tôi phối hợp chặt chẽ với khách hàng để tối ưu thiết kế về khả năng gia công, chi phí và hiệu suất sử dụng.

Tối ưu bản thiết kế nhằm nâng cao hiệu quả sản xuất và giảm chi phí

Hỗ trợ lựa chọn vật liệu phù hợp nhất với điều kiện sử dụng và ngân sách

Gia công mẫu nhanh để kiểm chứng thiết kế trước khi sản xuất hàng loạt

Cung cấp đầy đủ bản vẽ kỹ thuật, thông số và tài liệu sản xuất

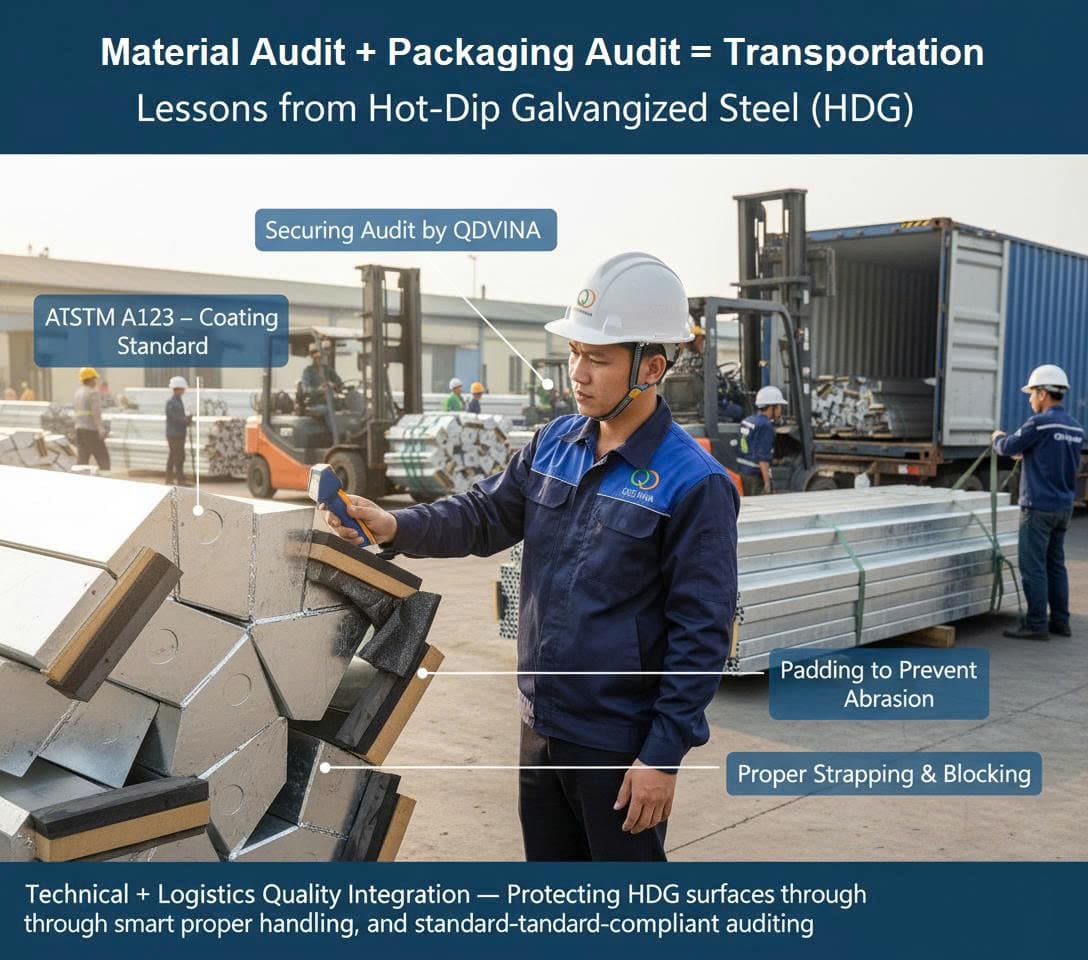

Chất lượng là yếu tố cốt lõi trong mọi hoạt động của chúng tôi. Hệ thống kiểm soát chất lượng toàn diện đảm bảo mỗi sản phẩm đều đáp ứng hoặc vượt tiêu chuẩn kỹ thuật và các tiêu chuẩn quốc tế liên quan.

Xác nhận chất lượng nguyên liệu trước khi đưa vào sản xuất

Theo dõi và kiểm tra liên tục trong từng công đoạn gia công

Đo kiểm kích thước, tính chất cơ lý và kiểm tra ngoại quan trước khi xuất xưởng

Báo cáo kiểm tra, chứng chỉ chất lượng và chứng nhận phù hợp tiêu chuẩn

Chúng tôi cung cấp dịch vụ đóng gói xuất khẩu và điều phối logistics trọn gói, đảm bảo sản phẩm được vận chuyển an toàn, đúng tiến độ và tuân thủ các yêu cầu xuất khẩu quốc tế.

Bao bì chắc chắn, phù hợp vận chuyển đường biển, đường hàng không và đường bộ

Chuẩn bị đầy đủ hóa đơn thương mại, packing list và C/O

Sắp xếp vận chuyển bằng đường biển, đường hàng không hoặc đường bộ

Cập nhật trạng thái vận chuyển theo thời gian thực cho khách hàng

Lợi thế trực tiếp từ nhà máy dành cho doanh nghiệp của bạn

Đội ngũ giàu kinh nghiệm, đồng hành cùng sự thành công của khách hàng

Kế hoạch sản xuất rõ ràng, cam kết tiến độ

Hệ thống quản lý chất lượng đạt chứng nhận ISO

Giá trực tiếp từ nhà máy, không qua trung gian

Liên hệ với đội ngũ của chúng tôi để trao đổi yêu cầu sản xuất và nhận báo giá chi tiết